Transformers are one of the most important inventions in the world, and quite literally transformed how electricity is transmitted, used, and how we can handle it safely. All electrical contractors, utility providers, and commercial sites with a transformer nearby should know what it is, and how it works.

So let’s take a look at a transformer’s working principle, how electrical repair staff needs to approach it, and what causes problems with it.

Understanding Electrical Systems – What Is A Transformer?

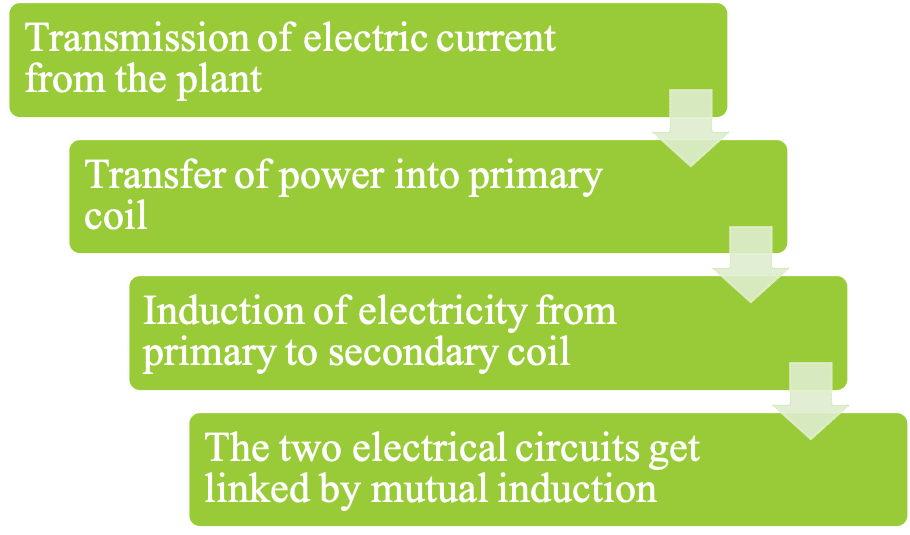

An electrical transformer is a static device that increases or decreases the voltage of current flowing through it to facilitate electrical transmission. The main operating principle behind transformers is mutual inductance, or the generation of electric current in one coil because of a flow of current in another.

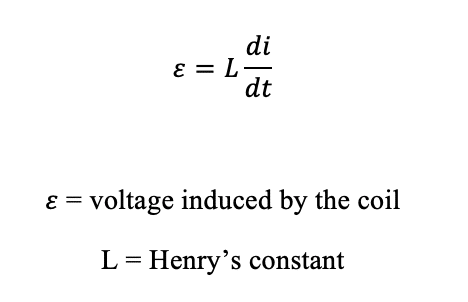

Whenever electrical current flows through anything, it creates an electric and magnetic field around it. When the transmitted current flows through one coil, it gets induced into the other coil due to the electric and/or magnetic field. The electric current produced within the coils due to mutual inductance can be calculated by the following formula:

The first coil which the current flows into is known as the primary winding. The second coil it moves through is known as the secondary winding. The working of a transformer can be represented by the chart below:

The goal of a transformer is to turn the high-voltage energy being transmitted from the plant to 220 v (or 110 v) usable energy.

Different Types of Transformers

There are several types of transformers, but they can be divided into two main groups.

Types by Design

Based on the design of transformers, there are two major types:

- Core-Type Transformer

Here the windings make up a considerable part of the core. This transformer is best suited for small and large applications. In this transformer, the cylindrical coils fit over the core, making it stronger.

- Shell-Type Transformer

As the name suggests, this type of transformer has a shell surrounding the coil. This shell is the core. The coils are located inside, in the form of discs separated by insulation and cooling ducts. These need strong mechanical braces to minimize the movement and humming sound.

These two types of transformers share many similarities, but one big difference is cost. Shell-type transformers are more common because of their capability of handling high-voltage applications, but they are more complex and built with more costly material, so they cost more than core-type transformers.

Types by Cooling Method

- Oil Filled Self-Cooling Transformer

- Oil Filled Water Cooling Transformer

- Air Blast Cooling Transformer

These transformers are used in large commercial facilities or industrial areas, placing significant loads on the transformer. Water and air blast types are much more efficient in operation but cost a lot more both when purchased, and when they’re in need of maintenance and repair.

If you are unsure which type of electrical transformer is best-suited for your needs, want troubleshooting related to your transformer, or have questions about your transformer(s), the expert electricians at Skyline are here to help you with any and all of your electrical needs. Get in contact with us today!